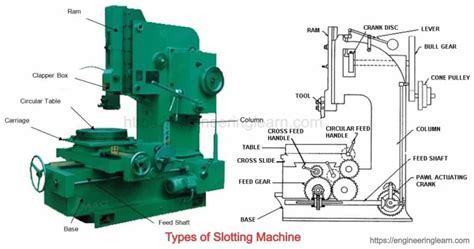

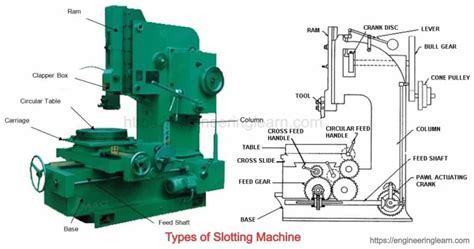

parts of slotting machine|Slotting Machine : Tuguegarao A slotter machine consists of the following different parts: Base. Column. Saddle. Cross-slide. Rotating or Circular table. Ram and tool head. Ram drive. Feed drive .

Health & Fitness Help workers in all roles get workwear that helps them perform, . MO 65202. Service: (573) 474-1024. Sales: (800) 455-7654. . Help keep staff and patients safe with hygienically-clean scrubs, lab coats, PPE, and disinfectants. SEE HEALTHCARE

PH0 · What is Slotting Machine?

PH1 · What is Slotter Machine

PH2 · Slotting Machine: Definition, Parts, Types, Operation, Application

PH3 · Slotting Machine: Definition, Parts, Types, Operation,

PH4 · Slotting Machine

PH5 · Slotter Machine: Parts, Types, Operations, Mechanism

PH6 · Slotter Machine: Definition, Types, Parts, Operation, Advantages

PH7 · Slotter Machine: Definition, Types, Parts, Operation, Advantages

PH8 · Slotter Machine: Definition, Types, Parts, Operation,

PH9 · Slotter Machine – Definition, Parts, Types, Working, Operations

PH10 · Slotter Machine

Unturned fue creado desde el principio con la idea de crear mods. Descarga contenido creado por otros jugadores, desde armas a vehículos y hasta niveles nuevos para explorar. Incluso tú puedes crear y subir lo que quieras. Crea tus propios mapas con el editor de mapas incluido. Todos nuestros mapas fueron creados con las mismas herramientas .

parts of slotting machine*******Written by Sachin Thorat in Manufacturing Technology. Table of Contents. Introduction to Slotting Machine : Common types of slotting machine. Puncher slotters. Precision slotters. Classification of slotting machine: .Parts of Slotting Machine. The parts of a slotting machines are described below; 1. Base. The base is the sturdy part of the machine which takes up all the cutting forces, vibrations and entire load of the machine. . Description of Slotter Machine Parts. Would you like to know the basic details of each part of the slotter machine? Let’s explore! Bed or base. The bed or base .parts of slotting machine Slotter Machine- Know Diagram, Parts, Working Principle, Types, Specifications and Applications. The slotter machine is a precision-driven tool in .

A Slotter Machine is another machine tool similar to a Shaper or a Planer Machine. Today we will discuss Definition, Types, Main Parts, Mechanism, Operation, Specification, Application, Advantages, and .A slotter machine consists of the following different parts: Base. Column. Saddle. Cross-slide. Rotating or Circular table. Ram and tool head. Ram drive. Feed drive .

What Are The Parts Of A Slotting Machine? A slotter machine consists of these following parts. Base; Column; Saddle; Cross-slide; Rotating or Circular table; .Here is an expanded description of the main parts of a slotter machine: Base: The base of a slotter machine serves as a robust and stable foundation that supports the entire machine.

Slotting machines can be used for all types of operations in which vertical movement of the tool is considered crucial and useful. Working Principle Of Slotting . These include the bed, which provides a stable base; the ram, which moves vertically; the tool head, holding cutting tools; and the worktable for material support. These parts work in harmony to facilitate precise slotting operations in various industries. Fig 2: Parts of slotter machine. A slotter machine consists of the following parts:-Base .

Therefore, the slotting machine is sometimes called as vertical shaper. In this article we will see slotter machine functions and types of slotting machine . See also: Major Shaping Machine parts and its Functions. .

A slotter machine is a production machine. This is a very old type of machine and was invented by BRUNEL. The slotting machine is similar to a vertical shaper. The ram carrying the slotting tool reciprocates in a vertical guideway of the machine. The Slotting Machine can manufacture flat and contour surfaces, and slots. .

slotter machine parts. Certainly! Here is an expanded description of the main parts of a slotter machine: . By performing these operations, slotting machines provide valuable machining capabilities in industries such as automotive, aerospace, general engineering, and more. They are versatile tools that can create flat and circular surfaces .The slotting machine can be used to perform a wide array of operations, of which we can find: Machining special and intricately shaped parts with both inner and outer profiles. It is designed to cope with long-running and especially heavy machining processes. In slot machining, the material selection is pivotal for the machining performance and quality of the milled. Common materials include: Aluminum: A go-to for efficient slot milling operations due to its machinability and good strength-to-weight ratio.It’s widely used in applications requiring lightweight and durable components, making it a .

#modimechanicalengineeringtutorials, #mechanicalmagicmechanicallearningtutorials,In this video easy explanation about Slotting Machine with construction, wo.Slotter Machine Parts. The main parts of the slotting machine are described below: Base or Bed. Column. Saddle. Cross-slide. Rotary Table. Ram. Tool Head. Speed Gear Box. Working Principle of Slotter Machine. The working principle of the Slotter Machine is very simple. In the slotting machine, the work item is placed in a vertical position on .

Parts of Slotting Machine. The parts of a slotting machines are described below; 1. Base. The base is the sturdy part of the machine which takes up all the cutting forces, vibrations and entire load of the machine. It is made from cast iron. 2. Column. The right rigid vertical part of the machine is the column. It houses the reciprocation and .

Slotting machines operate using a mounted blade in conjunction with a movable table that moves metal back and forth to create cuts and shapes. Shaping machines generally have a cutting tool that is mounted vertically. Because of this, slotting machines are many times referred to as vertical shapers. However, sometimes slotters are distinguished .

Slotting Machine Introduction: The slotting machine is a reciprocating machine tool in which, the ram holding the tool reciprocates in a vertical axis and the cutting action of the tool is only during the downward stroke.. Construction: The slotter can be considered as a vertical shaper and its main parts are:. 1. Base, column and table. 2. Ram and tool head .

Slotting Machine Parts. Rotary Table Dividing Head Centerlized Lubrication Pump Panel With Inching System Main Motor Tool Header Slotting Machine Wheels Stroke Adjustment Wheel Speed Chart .Definition and description of a CNC slotting machine. Components of a CNC slotting machine: Exploring the key elements that make it operational. 3. How CNC Slotting Machines Work . Step-by-step breakdown of the machining process of CNC slotting machines. The role of computer programming: Understanding how instructions are .

It can machine flat or contoured surfaces on the side of parts with a high degree of accuracy. This is especially true when done on a horizontal milling machine with a stiff arbor and short tool overhang. T-Slot Milling. T-slot milling is unique. Its main function is to cut T-shaped slots. These slots are crucial in industry and machining.parts of slotting machine Slotting MachineAll other parts of the machines exist on this basis. The base is made of cast irons which can carry compressive loads by various parts of the machine. Cast iron is a very strong and hardened material. The shock-absorbing capacity of cast iron is also high. . In the slotting machines, the metal is cut during the upward stroke, and no metal is .Despite the good advantages of a slotting machine some limitations still occur. The following stated below are the disadvantages of slotting machines: Required a skillful person to operate it. Rigid in construction. Read more: Slotter machine parts and their functions. Working principle of a slotter machine: The working of the slotter machine .Helical Gears: We give constant strokes in the slotting machine and each stroke gives a reaction on the main gear teeth. For such continuous stroking, gears must be rigid to work for 15 years Taking into consideration the quality and accuracy of the job, we are using DP-8 Heavy Helical Gears in our slotting machine. It is made from GCI-25 Grade casting. It is a machining procedure that uses a spinning tool with many cutting edges. A slot milling operation’s main determinants are the workpiece’s material properties and the necessary dimensions of the slot (width, depth, and undercut).. The proper selection of tools, feed rate, speed, and cooling fluids can all have a significant impact .

See top SEO metrics for free as you browse the web. More Free SEO Tools Explore all the free SEO tools Moz has to offer. Moz What is your Brand Authority? . For local SEO, accuracy matters. Moz Local helps you easily create and manage your local business listings on Google, Facebook, and other sites to help consumers find and choose your .

parts of slotting machine|Slotting Machine